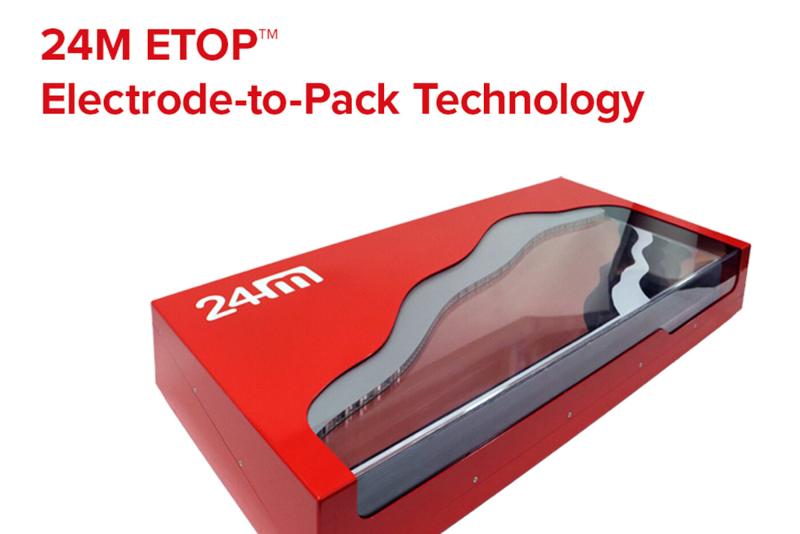

In the world of electric mobility and energy storage systems, a groundbreaking innovation has emerged. The 24M Electrode To Pack (ETOP) system is revolutionizing battery pack technology by streamlining the packaging process and eliminating the need for individual cells and modules. This article explores the advantages, features, and potential impact of this game-changing battery technology.

Advantages of the 24M Electrode To Pack System

Discover the game-changing advantages of the 24M Electrode To Pack system

The 24M Electrode To Pack (ETOP) system offers a range of advantages that are set to revolutionize the electric mobility and energy storage industry. One key advantage is the streamlined battery pack system, which eliminates the need for individual cells and modules. This not only simplifies the manufacturing process but also reduces costs and waste.

Furthermore, the 24M ETOP system achieves unmatched energy density by removing inactive materials within the battery pack, resulting in higher performance and improved range and cycle life. Additionally, the system offers enhanced safety features and provides pack design flexibility, allowing for various configurations.

Innovative Features of the 24M Electrode To Pack System

Explore the innovative features that set the 24M Electrode To Pack system apart

The 24M Electrode To Pack (ETOP) system introduces several groundbreaking features that revolutionize battery pack technology. One notable feature is the achievement of electrode packing efficiencies of over 70%, the highest in the industry. This results in optimal pack-level volume utilization efficiency.

Moreover, the system enables unit electrodes to be connected in a combination of series and parallel, eliminating the need for additional connection components and reducing overall pack costs. The 24M ETOP system also offers higher packing efficiencies and energy density, leading to improved range and cycle life for electric vehicles and energy storage systems.

Additionally, the 24M SemiSolid™ Electrode and Unit Cell technology provide unmatched safety when subjected to mechanical abuse, ensuring reliable and secure operation.

Collaboration with Freyr: Expanding the Reach of the 24M Electrode To Pack System

Learn about the collaboration between 24M and Freyr and its impact on the adoption of the Electrode To Pack system

24M has formed a strategic collaboration with Freyr, one of the leading battery manufacturers, to commercialize the Electrode To Pack system. This collaboration aims to produce 24M battery cells for automotive, maritime, and energy storage applications.

Freyr's battery factory in Mo i Rana, Norway, will have an annual capacity of 45 GWh, allowing for significant production scale. This partnership will not only accelerate the adoption of the 24M Electrode To Pack system but also contribute to the growth of sustainable transportation and energy storage solutions.

Partnerships and Clientele: Driving the Adoption of the 24M Electrode To Pack System

Discover the key partnerships and clientele that support the widespread adoption of the 24M Electrode To Pack system

24M has garnered significant support from renowned industry players, including Volkswagen Group, Kyocera, Itochu, GPSC, and Fujifilm. These partnerships enable the integration of the 24M SemiSolid™ and Unit Cell technology into next-generation lithium-ion batteries.

For instance, Volkswagen Group has secured access to the 24M SemiSolid technology for its future lithium-ion batteries, highlighting the industry's recognition of the system's potential. Additionally, Kyocera has already commercialized its Enerezza home energy storage product using the 24M technology, further validating its effectiveness.

These partnerships and clientele demonstrate the widespread acceptance and adoption of the 24M Electrode To Pack system, paving the way for a more sustainable and efficient energy future.

The Future of Battery Technology: Transforming the Electric Mobility and Energy Storage Landscape

Explore the potential impact of the 24M Electrode To Pack system on the future of battery technology

The introduction of the 24M Electrode To Pack system marks a significant milestone in battery technology. By eliminating the need for individual cells and modules, this system offers unparalleled energy density, cost savings, and performance improvements.

With the support of key partnerships and growing clientele, the adoption of the 24M Electrode To Pack system is poised to transform the electric mobility and energy storage landscape. As battery technology continues to evolve, innovations like the 24M Electrode To Pack system bring us closer to a future of cleaner and more efficient transportation and energy solutions.

Conclusion

The 24M Electrode To Pack (ETOP) system represents a significant breakthrough in battery pack technology. By streamlining the packaging process and eliminating the need for individual cells and modules, this innovative system offers unmatched energy density, cost savings, and performance improvements.

With its advantages, such as higher packing efficiencies, improved range and cycle life, enhanced safety features, and pack design flexibility, the 24M Electrode To Pack system is poised to revolutionize the electric mobility and energy storage industry.

Through strategic collaborations, partnerships, and growing clientele, the adoption of this system is gaining momentum, driving us towards a future of cleaner and more efficient transportation and energy solutions.

FQA

What are the key advantages of the 24M Electrode To Pack system?

The 24M Electrode To Pack system offers advantages such as streamlined packaging, cost reduction, higher energy density, improved range and cycle life, enhanced safety features, and pack design flexibility.

How does the 24M Electrode To Pack system differ from traditional battery pack systems?

Unlike traditional systems that rely on individual cells and modules, the 24M Electrode To Pack system eliminates the need for these components, simplifying the manufacturing process and reducing costs and waste.

What collaborations and partnerships support the adoption of the 24M Electrode To Pack system?

24M has formed strategic collaborations with companies like Freyr and Volkswagen Group, securing access to their manufacturing capabilities and expertise. Additionally, partnerships with Kyocera, Itochu, GPSC, and Fujifilm contribute to the widespread adoption of the system.

How does the 24M Electrode To Pack system contribute to a sustainable energy future?

By delivering unmatched energy density, cost savings, and performance improvements, the 24M Electrode To Pack system accelerates the transition to cleaner and more efficient transportation and energy storage solutions, reducing our reliance on fossil fuels.